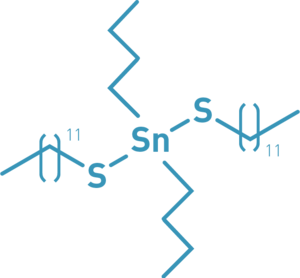

| Name | Dibutyltin Laurylmercaptide |

| CAT | 1185-81-5 |

| Formula | C32H68S2Sn |

| BNT Product Name | BNT-CAT 490 |

| Synonyms | Dibutyl dodecyl thiostannane Dibutyltin bis-(lauryl mercaptide) di-n-butyl bis-(dodecylthio)tin DBTLM |

Economic Importance of Dibutyltin Laurylmercaptide

Dibutyltin laurylmercaptide is mainly used as a catalyst and stabilizer. For example, various polyurethane-based systems are catalyzed by DBTLM, for example for two component adhesives or sealants in which it can influence the speed of curing.

Dibutyltin laurylmercaptide can also be used for the production of polyurethane foams that have to withstand adverse weather conditions without yellowing or wear out too quickly. The foam is produced by foaming and solidifying a reaction mixture in heatable molds. A special catalyst combination is required to ensure that the material obtains the desired properties during forming. Methods of this type are used for lightweight and durable parts in the construction of furniture or vehicles.

Further examples in which dibutyltin laurylmercaptide can be employed are the plastic recycling and the formulation of fluorescent amplifiers, which are used e.g. in X-ray technology.

However, DBTLM is not only catalytic, but also has a stabilizing effect on other materials, which is why it is needed as a stabilizing agent for polyvinyl chlorides (PVC plastics).

Transport and Storage

Dibutyltin laurylmercaptide containers should be kept dry, tight and sealed and in a well-ventilated and cool place. If proper handling and storage are present, no decomposition should occur for at least 6 months. Thermal decomposition occurs from 228 °C. Heat and direct irradiation by the sun should be avoided.